General

-

How do I contact my sales person?

Head over to our contact page which includes email and phone numbers for all of our sales staff.

-

What is your turnaround time?

Our standard turnaround time is two weeks from the receipt of your order.

-

Do you do rush orders?

Rush orders are available. Please call us today to see if your order can be fit into our production schedule. Rush charges may apply during peak business seasons.

-

How do I pay for my order?

We accept cash, check, and charge (Visa, MasterCard, and American Express).

-

How will I receive my order?

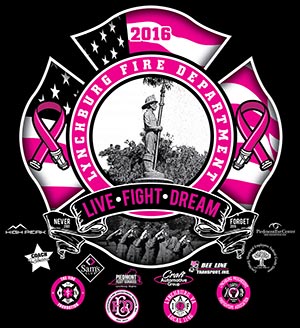

Orders can be picked up at any of our four locations in Blacksburg, Charlottesville, Lynchburg and Roanoke. Orders can also be shipped UPS, standard charges will apply. Some companies promise free shipping, but then build it into your cost elsewhere with an additional markup. We prefer to keep our pricing straightforward and honest, so that you can make the appropriate decisions.

-

May I cancel an order?

Orders that have not been produced can be cancelled. However, depending on when the order is cancelled, art charges, digitizing fees, or garment restocking fees will be charged to cover the costs already incurred.

-

What is your return policy?

We pride ourselves in exceeding the industry standard and providing exceptional customer satisfaction. However, due to the labor intensity of custom orders we cannot accept returns on decorated garments under any circumstances.

-

Will I receive a printed sample?

Because of the labor intensive setup of screen printing, it is not normally possible to print samples. Blank samples for sizing purposed can be ordered. Please contact us for information and charges.

-

What are your standard printing locations and sizes of imprint?

Adult garments: 3.5 inches square is our standard pocket area print size. If we're printing on pocket it's 3 inches square. Back art is printed at 12 inches square. Youth garments: Back art is printed at 9 inches square.

Art

-

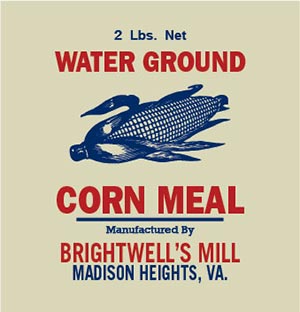

Can you produce artwork based on an idea?

We have a full service art department which can fine tune artwork you’ve done, or produce artwork from your concept or idea. There are aspects to artwork for screen printing which are specific to only screen printing and are crucial to getting a great looking print. For instance, depending on the specifics of the design, you may want adjoining colors to overlap, meet exactly, or have a small space between them. Our artists are all experts with years of experience producing great shirts, we charge artwork at $30.00 per hour.

-

What file format should be used for provided artwork?

Our artists use primarily Apple computers running Adobe Illustrator. So if you’re providing artwork, it needs to be in vector format. We prefer to be provided illustrator files, eps, or vector pdf files. If questions remain our art department will be glad to discuss acceptable file types.

Technical information on recommended art format:

-For full color images, 4 color process and continuous-tone images with 300dpi at actual size.

-All fonts (printer and screen) must be included with your file or all text should be converted to outlines or curves.

-Software Applications: Files saved in any of the following applications are acceptable: Adobe Illustrator CS5 and below & Photoshop CS5 and below.

-Please submit Vector art as eps, ai or pdf.

-All customer provided digital files should be evaluated by one of our artists before any potential art charge can be estimated.

-

How do I proof my artwork?

For the protection of all parties involved, all artwork must be proofed by you prior to any order being produced. You will have the opportunity to view a representation of your job electronically via email or a web based art approval site. Please be aware that colors do vary on different monitors and inks on colored shirts have some interaction which will change the color or change the way a color is perceived.

-

Do you do PMS color matching?

We stock a wide variety of standard ink colors. If it is necessary to mix ink to match a specific color, there will be a $15.00 per color charge. A PMS number or color swatch must be provided to match a non standard ink color. Due to variations in garment colors and reaction to dyes in certain colored shirts, some color variation should be expected. We strongly suggest that if any way possible you use standard ink colors.

Garments

-

Who supplies the garments to be printed?

We prefer to purchase the garments for your job and we do this for the overwhelming majority of jobs we produce. We work with dozens of suppliers and can get an almost unlimited range of garment styles and colors. If High Peak orders the garments, we can be sure they are garments which work well in the screen printing process. This reduces the likelihood of garment dye interaction with ink, garments with treatments that adversely affects inks, and garments which can’t stand the heat required to cure the ink without shrinking or scorching. Also, if we provide the garments we can replace any garments lost during production.

-

May I supply garments? (contract printing)

If you provide the garments to be printed, there are some potential issues of which you need to be aware. Recently there's been an explosion in the market of moisture wicking and other high tech performance garments. Many are problematic when printing, due to ink adhesion and scorching issues caused by the temperatures required to cure ink. Additionally if there are misprints, etc., since we didn't provide the garments we can't replace those which get damaged. It's safer for all parties and we prefer whenever possible to provide garments we know will work for the intended purposes.

-

Can you guarantee exact quantities?

Please notify your sales person if an exact quantity is necessary. Losses during production are always a possibility, please make your salesperson aware if an exact quantity is essential.

-

Why are there minimum quantities for screen printing?

The screen printing process is fairly costly during the setup stage, both in materials and labor. It’s in nobody’s interest to spend a lot of money setting up a job only to print a few shirts. We recommend our direct to garment method or heat transfer printing methods for small quantities.

-

What's the minimum amount of shirts I have to order?

The minimum number of shirts to screen print depends on the number of ink colors included in all print locations. If you can keep the total number of ink colors (screens) to 1 or 2 we can print as few as 20 shirts. More ink colors drive up the number of shirts required to be printed. The next answer below provides a general guideline.

-

What are my alternatives for print jobs with small quantities and/or large numbers of colors?

High Peak Sportswear has new DTG (direct to garment) equipment which allows printing on garments without screens and setup charges. The process has some limitations, but is a good option for small quantity jobs. Ask your salesperson if this process will work with your job.

High Peak Sportswear has a printer which will print ink onto a special paper which can then be heat transfered onto a garment. This process also has limitations, but may work well with your job, again please ask your salesperson.

-

May I group items of different style, size and color in the same order?

There is no simple answer to this, most of the time it’s not a problem, sometimes it’s a major problem. Below are some common considerations, but before assuming it is or is not ok to group styles, sizes, or colors please consult one of our sales staff or artists and they can give you a definitive answer.

Grouping different styles: Some items such as short sleeve and long sleeve may be grouped with no problems. However for example, full front prints on t-shirts probably won’t fit on the front of a pocket tee, or a hoodie with a pouch. Mixing garments with different composition is likely not possible, to get vibrant prints we use different inks on polyester shirts from 100% cotton shirts, jackets require a completely different type of ink and printing setup from t-shirts.

Grouping different colors: Again, to determine if this is possible your salesperson or artist will need to understand the specific job. One color text can be printed on some shirts in one color of ink, and then the ink changed for printing on other colored shirts, an ink change fee will apply. However if there are multiple colors of ink, it gets much more complicated. Also, some artwork will get a “negative” look if the ink colors are changed from dark to light. Think of a baseball printed using white ink having dark stitches. If you used the same artwork and just changed the white ink to black ink for light shirts, you’d have a black baseball with light stitches which will look strange. In this case, to get the baseball to look right there would be different artwork for the dark and light shirts.

Grouping different sizes: This is part of the normal routine, but still there are considerations. If the job includes sizes adult M through XL the artist will design the artwork as large as will fit on the Medium and this is normally fine for all the shirt sizes. However if you have a job with youth small through XXXXL the artwork which will fit on the youth small will look tiny on the XXXXL. Having adult sized and youth sized artwork is one solution, but it creates a second setup and potential charges depending on shirt quantities.

-

Can I have names and numbers ironed on a shirt?

Yes, names and numbers are available to be ironed onto shirts for ball teams and more. We have many colors of vinyl stock and we have a plotter style cutter to cut names. Ask your salesperson for available color options.

Pricing

-

Why is printing on dark shirts more costly than white?

Printing on dark garments is much more labor intensive and significantly slower than printing on light garments, thereby costing more. One example, additional white ink is often required to be printed prior to other colors to get bright vibrant colors. Also, darker colored garments cost more to purchase that lighter colored ones, white are generally the cheapest blanks to purchase.

-

Why is there an ink color change fee if I change ink colors.

If your order requires changing ink colors in the design, there is a $10.00 charge for each screen which must be changed. The process of removing ink from a screen is difficult and time consuming, requiring use of solvents and often taping and realigning the screens.

-

What setup/screen charges will I incur?

A screen is required for each ink color of each print location. The charge per screen is $20.00, however one screen charge is eliminated for each 20 shirts ordered. For example, an order of 40 shirts with 3 colors of ink and therefore 3 screens would incur 1 $20.00 screen charge. The same 3 screen print job with 60 shirts would have no screen charge. Talk with your artist about how to eliminate ink colors from your job thereby eliminating screen charges.